FRP grating has five advantages over traditional grating

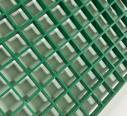

FRP grating is a plate-like material that consists of numerous openings. It is manufactured using glass fiber as a reinforcing agent and unsaturated polyester resin as the base material. This combination utilizes specialized processing technology, resulting in remarkable properties such as lightweight, high strength, corrosion resistance, flame retardancy, and anti-slip characteristics. FRP grating is predominantly utilized in various industrial sectors, including ground surfaces, trench covers, platforms, and ship decks. Given its essential role in everyday life, FRP grating manufacturers are widely available.

Advantages of FRP Grating Over Traditional Grating

1. Combatting Aging and Rusting

Traditional gratings often suffer from issues such as aging and rusting. They possess low strength ratings and are vulnerable to atmospheric and acid-base corrosion. In contrast, FRP grating effectively addresses these shortcomings, serving as an excellent substitute for older steel, plastic, and metal gratings. Furthermore, it is available at a reasonable price.

2. Lightweight and Cost-Effective

FRP is a composite material made from resin and glass fiber. It has a relatively low density. When compared to steel grids, FRP is approximately 1/4 the weight of steel and only 2/3 the weight of aluminum. Its strength surpasses that of rigid polyvinyl chloride by tenfold and is greater than aluminum, reaching the strength level of standard steel. Its lightweight nature significantly reduces the load on foundation support, which in turn lowers overall project costs. Installation is straightforward, requiring no fire or heavy lifting equipment, and necessitating only minimal labor and power tools, thus further reducing installation expenses.

3. High-Quality Appearance

High-quality FRP grid products exhibit an appearance free of noticeable cracks, minimal pores, pure color, good transparency, adequate toughness, high strength, and a smooth surface. In contrast, inferior FRP grid products often show cracked surfaces, numerous pores, impure colors, and inadequate gloss, contributing to a shorter lifespan.

4. Industry Acceptance

The fiberglass grid plate has received 68% unanimous approval within the industry. It can accommodate various conditions and meet dynamic consumer demands. Although it has a lower density than other materials, this does not impede growth potential. FRP demonstrates excellent resistance to corrosion, especially when enhanced through aesthetic design, allowing it to withstand rain and snow erosion.

5. Material Composition and Quality

The FRP grating material is composed of resin, FRP fiber, and calcium filler in a balanced ratio of 1:1:1. High-quality FRP gratings utilize premium resin: specifically, 196 unsaturated phthalic resin, which is colorless and transparent. This type of resin has low viscosity, low heat release, minimal shrinkage, rapid curing properties, high compatibility, and a glossy finish. Products made with inferior resin show the opposite characteristics: they will be opaque, have high viscosity and heat release, significant shrinkage, slower curing times, and poor compatibility, resulting in FRP gratings that are porous, fragile, and low in strength.

Installation Processes

FRP grating is produced using several methods, one being the reciprocating winding method (fixed length method). In this process, the dipping tank and the rotating mandrel move in a reciprocal manner. The inclination angle of the long fiber glass is managed to control wrapping angles, while computer systems regulate the movement of the dipping tank. This results in successive layers being wrapped until the desired specifications are achieved. Once winding is complete, the resin solidifies within the product, and the mandrel is removed post-vulcanization.

Comments

0