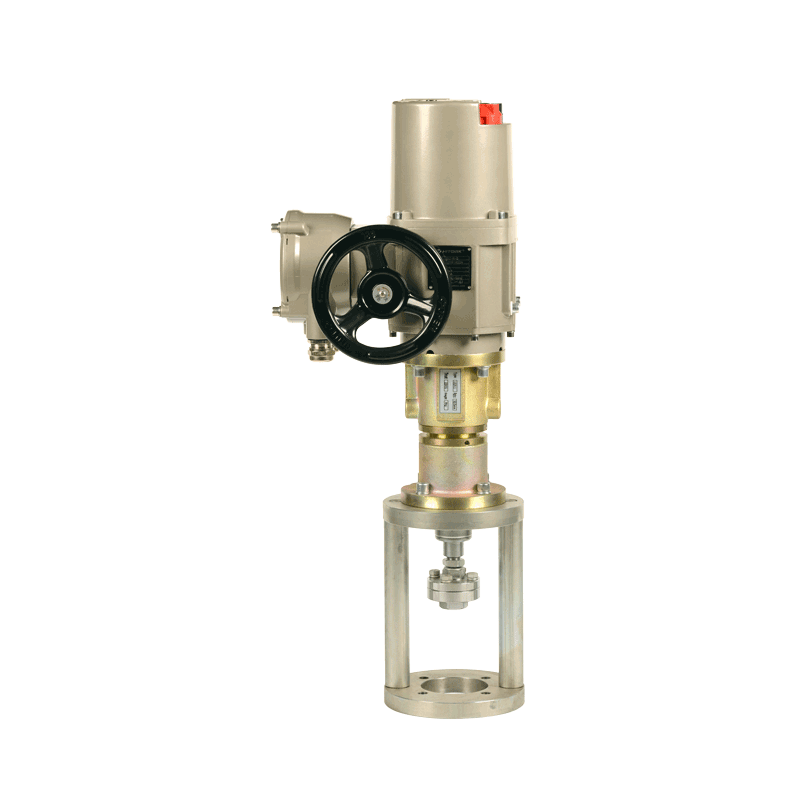

Unveiling Electric Actuators: Types, Applications, Benefits, and Design

In the world of automation and robotics, electric actuators serve as indispensable components, translating electrical energy into mechanical motion. These devices play a vital role across various industries, offering precise control, reliability, and versatility in a wide range of applications.

Types of Electric Actuators:

Linear Actuators: Linear actuators convert rotary motion into linear motion, enabling precise positioning of loads along a straight path. They come in various designs, including screw-driven, belt-driven, and linear motor-driven actuators, each suited for specific applications based on load capacity, speed, and accuracy requirements.

Rotary Actuators: Rotary actuators produce rotational motion, allowing for the controlled movement of objects around a central axis. These actuators can be electrically driven using motors such as DC motors, stepper motors, or servo motors, providing angular displacement with high precision and torque.

Piezoelectric Actuators: Piezoelectric actuators utilize the piezoelectric effect to generate motion in response to an applied voltage. These actuators offer extremely fast response times, high precision, and nanometer-scale resolution, making them suitable for applications such as nanopositioning, microscopy, and optical alignment.

Applications of Electric Actuators:

Industrial Automation: Electric actuators are widely used in industrial automation systems for tasks such as robotic assembly, material handling, and precision positioning of machinery. Linear actuators, in particular, find applications in conveyor systems, packaging machinery, and CNC machining.

Aerospace and Defense: In the aerospace and defense industries, electric actuators play critical roles in flight control systems, missile guidance mechanisms, and unmanned aerial vehicles (UAVs). Their compact size, lightweight construction, and precise control make them ideal for use in aircraft components and military equipment.

Medical Devices: Electric actuators are integral to various medical devices, including surgical robots, patient lifts, and diagnostic equipment. Linear actuators are employed in hospital beds, adjustable tables, and mobility aids, enhancing patient comfort and accessibility.

Benefits of Electric Actuators:

Additional reading:How to Save Money When Buying large format heat presses

4 Tips to Select the Right Laptop for Your Needs

How Effective is Briquetting Equipment for Businesses?

How to Choose Custom Shielded Instrument Cases?

Key Questions to Ask When Designing Custom Shielded Instrument Cases

4 Tips to Select the Perfect Calcium Silicate Board Production Line

How to Create a Calcium Silicate Board Line?

Precision and Accuracy: Electric actuators offer precise control over motion, allowing for accurate positioning and repeatability in industrial and scientific applications.

Efficiency: Compared to hydraulic or pneumatic actuators, electric actuators are more energy-efficient, with no need for continuous power consumption when holding a position.

Maintenance: Electric actuators require minimal maintenance, as they have fewer moving parts and do not require hydraulic fluid or air supply.

Flexibility: Electric actuators can be easily integrated into automated systems and controlled remotely using electronic interfaces, offering flexibility in design and operation.

Design Considerations:

Load Capacity: Selecting an electric actuator with the appropriate load capacity is crucial to ensure optimal performance and safety in the intended application.

Speed and Stroke Length: Considerations such as desired speed, acceleration, and stroke length influence the choice of electric actuator design and specifications.

Environmental Conditions: Factors such as temperature, humidity, and exposure to contaminants must be taken into account when designing electric actuators for use in harsh or demanding environments.

Control Interface: Electric actuators can be controlled using various interfaces, including analog signals, digital communication protocols (e.g., CAN bus, Modbus), and programmable logic controllers (PLCs), depending on the application requirements.

Electric actuators are versatile and reliable components widely used in automation, robotics, and motion control systems across diverse industries. Understanding the different types of electric actuators, their applications, benefits, and design considerations is essential for engineers and designers seeking to leverage their capabilities in developing efficient and innovative solutions. With advancements in technology and design, electric actuators continue to play a pivotal role in driving automation and enhancing productivity in various fields.

How Many Cartons Fit on One Pallet?

How Many Cartons in One Pallet: Explained

How to Customize Finned Tube Exchangers Effectively?

The Advantages of Embracing Finned Tube Exchanger Customization

Key Considerations to Make When Selecting a Pet Food Dispenser

Essential Guide to Using Feed Pellet Crumblers

The Benefits of Using Private Label EV Battery Pack Assembly

Related Articles

Comments

0