1. The difference between forging and casting(1) Conceptual differencesCasting: It is the transformation of shapeless molten metal into a shaped solid.

Forging: It is a solid that turns one shape of solid into another.Casting is like you play with wax, you buy wax (scrap steel, or pig iron) and you turn that wax into a liquid and put it into a mold, so you get something in a different shape. (solid-liquid-solid).Forging, like the process of making dough, you knead small pieces of dough and put them into molds to make different shapes. It is almost the case that a solid can change its shape to something else (solid-to-solid) at high temperatures.Casting is the process of casting molten metal into a model to obtain a casting. The casting profession focuses on the metal melting process and the process control during the casting process.Forging is plastic forming in the solid state, which is divided into hot working and cold working, such as extrusion, drawing, pier thickness, punching, etc.(2) Forging is slowly formed, and casting is one-time molding.Casting: Molten liquid metal fills the cavity for cooling. It is easy to generate pores in the middle of the workpiece.

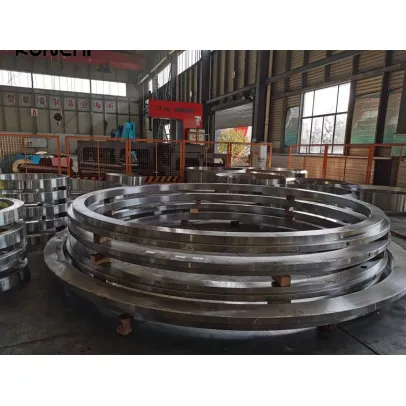

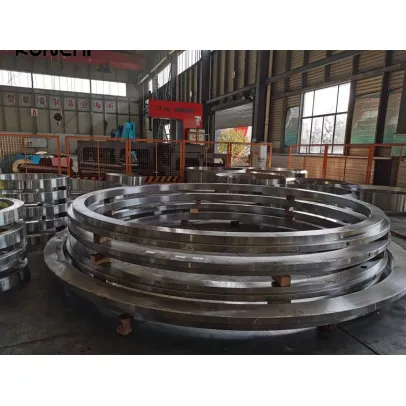

Forging: It is mainly formed by extrusion at high temperatures. Grains in the part can be refined.2. The difference between open forging and die forgingOpen forging is a processing method in which the heated metal blank is placed on the top of the forging equipment and between the lower iron, and the impact force or pressure is applied to directly make the blank plastically deformed, so as to obtain the required forging. Due to the simple shape and flexible operation of forgings, open forging is suitable for the production of single pieces, small batches and heavy forgings.Open forging is divided into manual free forging and machine free forging. Manual free forging production efficiency is low, labor intensity, only used for repair or simple, small, small batch of forging production, in modern industrial production, machine free forging has become the main method of forging production, in heavy machinery manufacturing, it has a particularly important role.Die forging is called model forging, and the heated blank is placed in a forging die fixed on the die forging equipment for forging.Die forging can be performed on a variety of equipment. In industrial production, most of the hammer die forging uses steam-air hammer, with a tonnage of 5KN~300KN (0.5~30t). Hot die forging presses are commonly used for die forging on presses, with a tonnage of 25000KN~63000KN.The forging die structure of die forging includes single-die hall forging die and multi-die bore forging die. Single-die forging die, which uses dovetail groove and wedge to fix the forging die to prevent it from falling out and moving left and right; The combination of key and keyway is used to make the positioning of the forging die accurate and prevent forward and backward movement. The single die chamber is generally the final forging die chamber, and the forging often needs to be hammered by air to make the billet, and then formed by the repeated hammering of the final forging die chamber, and finally the forging is taken out to cut off the flash.3. The difference between casting, forging, stamping, and die casting(1) Casting is the melting of raw materials to allow them to form naturally in a molding moldForging is to heat the raw material to a certain temperature and then use tools to forge and form;

Stamping is to stamping raw materials with suitable stamping dies;Die-casting is based on casting, and the melted raw materials are injected into the mold by pressure to obtain higher density or more precise shape;Casting: Molten liquid metal fills the cavity for cooling. It is easy to generate pores in the middle of the workpiece.(2) Forging: It is mainly formed by extrusion at high temperature, which can refine the grains in the workpiece, and the thickness of the parts is basically the same, which is suitable for stamping with plate forming.The thickness of the forging parts is very different, the shape is complex, and it is not subject to heat, and die-casting.1. Casting is divided into two types: high-pressure casting and low-pressure casting. To put it simply, after the metal is melted, the pressure of the mold is different, and the temperature at which the metal is heated is different from the machine used for casting.2. Forging is also a casting method, the difference is that the temperature during forging is lower, and some can make the metal into a finished product in a semi-molten state.3. Stamping is the process of making semi-finished products into finished products with punches and other machines at room temperature.4. Die-casting is also a way of high-temperature casting, when encountering castings with complex structure and greater difficulty, you can use a die-casting machine to heat the metal into a liquid state, press it into the mold, and open the mold to take out the product after cooling.

Comments

0